|

SITE

INDEX

QUICKENING

NEWS

PREPARATIONS

1.

Food

2.

Manna

Meals

3.

Water

4.

Sanitation

5.

Medical,

health

6.

Kerosene heaters and cookers

7.

Lighting

8. Wood

cooking and heating

9. Communi-cations

10. Essential

Tools

11. Home

built items

12.

Electrical; generators

and power

13. War

preparedness

14.

Gardening

SITE

INDEX

Miles Stair's SURVIVAL

SHOP

HOME

RADIATION

INDEX & JET STREAM

PROPHECY

COMMENTARY

BY MILES

BOOKLETS

BY MILES

GUEST

SUBMISSIONS

PHOTO

INDEX

LINKS

SITE

INDEX

Miles Stair's SURVIVAL

SHOP

|

|

Making Sheathes

for Tools

Tools need to be kept sharp and rust-free so

they are ready to use when needed. That especially

applies to tools saved and stored to be used in an emergency

situation.

Sheathes for small tools

allows them to be carried on a tool belt, the tools being

selected for the particular job at hand. Sheathes for

larger tools allow the tools to be safely strapped to carts

and packs while covering sharp edges to enhance safety.

Sheathes can be made

from a variety of materials such as old Levi's, scrap leather,

cheap East German packs and even PCV pipe and barrels.

The sheathes illustrated

below are ones I made to fit specific tools with materials

close at hand. No attempt was made to make the sheathes

fancy because they are for working TOOLS, not arm chair

theorists to show off something they would never use.

Amost all of these tools

can be purchased inexpensively on eBay, often in very good

condition. They need only be cleaned, oiled and

sharpened to put back into service.

Click on the photos to

enhance them.

BERNARD PLIERS

|

Bernard

pliers were perhaps the first readily available

multi-tools. These pliers were patented July 19,

1892 and are still excellent tools. The flat, parallel opening jaws with compound

leverage applied massive clamping power and the

side-cutters were very powerful for cutting tempered fence

wire. These pliers were carried by farmers and

ranchers on a daily basis for decades. There is a

groove in the middle of the top jaw that straightens wire,

and the design of the compound leverage allows wire to

pass between the handles. |

|

SHEATHES FOR BERNARD PLIERS

|

Different

techniques had to be used for making the sheathes for the

large and small Bernard Pliers due to the weight of the

pliers. Notice that not only are the large pliers

longer but they are considerable thicker. |

|

Small Bernard Plier Sheath

|

The small Bernard Pliers were easy to make a

sheath for using a strip from a pant leg from worn out

Levi's. The back side of the sheath at right shows

the sewn on belt loop. The bottom of the sheath was

doubled Levi canvas, which has more than enough strength

to hold the 6 1/2 ounce pliers. |

|

|

The front side of the sheath for the small

pliers shows the Levi button to hold the sheath closed.

These buttons are very easy to install and work well for

thick canvas and even inner tube rubber. They are

sold as ''batchelor buttons," "Logger buttons,"

Suspender buttons," etc. |

|

Large Bernard Plier Sheath

|

The large Bernard Pliers weigh 1 pound, 3

ounces, so much that they would quickly ''worry'' their

way through Levi canvas in a very short period of time.

Hence, a plastic insert was needed to place inside the

sheath to hold the weight and sharp edges of the pliers.

An 8 fl oz Ronson lighter fluid bottle proved to be an

outstanding fit for the pliers, holding the pliers so they

would not rattle and firmly enough so there is no stress

at all on the old Levi cloth. The back of the

sheath is shown. |

|

|

At right is

the finished sheath for the large Bernard pliers.

The belt loop is full width and supports the weight of

these pliers easily. The sheath was made so that the

handles protrude slightly to ease pulling them from the

sheath for use. |

|

HATCHET

A good framing hatchet can be

extremely useful, particularly around a wilderness camp as

they usually have much better steel then a cheap camp

hatchet and nice broad cutting edge.

The left photo above shows my refinished framing hatchet.

But to keep the hatchet sharp and in perfect condition, a

good sheath is required. I used an East German

grenade pouch and some rivets to make the sheath shown

above. The grenade pouch was less than $3.00 from Sportsmansguide.com.

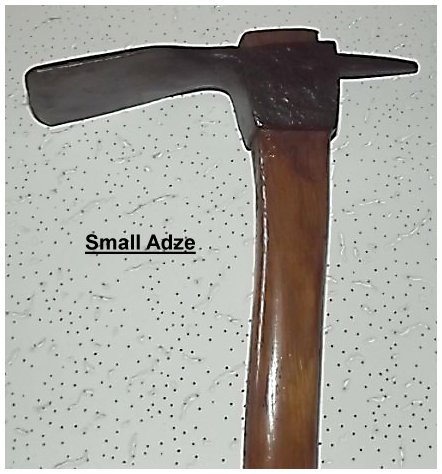

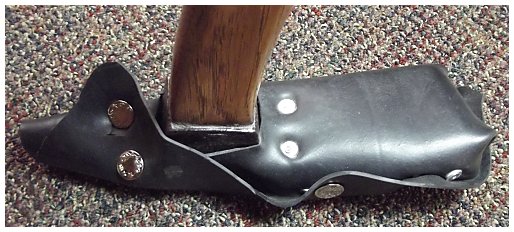

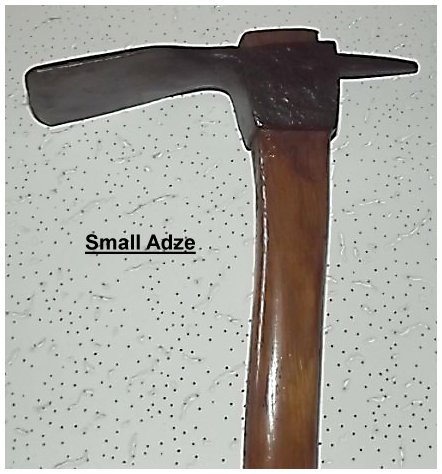

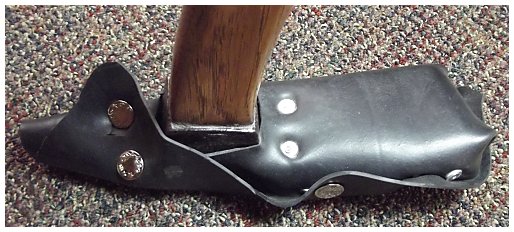

SMALL ADZE

|

|

Small

adze in sheath made from a truck inner tube. A

plastic bottle was cut and pop riveted in to cover the

sharp blade edge (right, above). Jeans buttons keep it

closed. |

|

A small adze is extremely

useful for shelter building. The sideways edge keeps

your knuckles away from the surface compared to an axe.

They work extremely well for smoothing log surfaces in

confined areas such as the inside of an expedient shelter

(dugout) and for logs which make up the roof of the shelter.

If a shelter is to be rain- and wind-proof, it must be

sealed. The easiest way to accomplish that is to use

an adze to chop off high spots, smooth down branch roots,

and make notches so the logs are interlocked. The

roof is then covered with a few inches of dirt and the

soil smoothed out. A very fine film of plastic sheet

can be carefully laid out over the soil and then be

covered with a few more inches of soil and sod. That thin

film of plastic sheet is the wind and rain protection for

the shelter, and being sandwiched between layers of sod

has automatic UV protection so it will last for years.

Sharp projections having been eliminated by the adze, the

soil protects the delicate plastic film while holding it

in place. The logs on the sides of a shelter should

be chinked with moss (or whatever is available), for which

the back of the adze has been designed. Shelters

such as a dugout should have a plastic film placed on the

outside of the logs before backfilling with dirt. If

smoothed with the adze there should be few sharp

projections to cut the plastic film, but there will still

be some holes. Nevertheless it is far better

moisture protection than nothing at all. Google "Ziemlanka"

for more images of traditional dugouts.

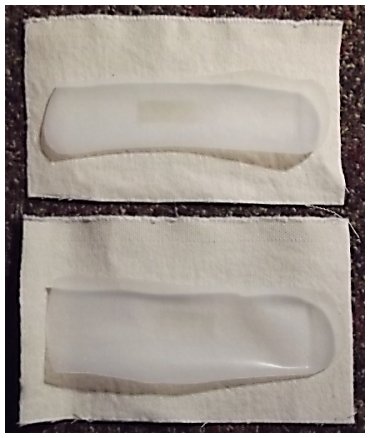

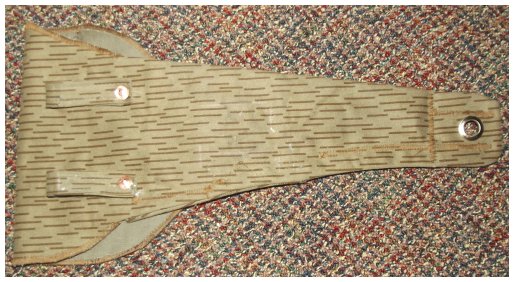

BELT SHEATH FOR SPOKESHAVE

Above left, inserts cut from a

gallon milk jug. These are then sandwiched between

two layers of canvas and each half sewn. The halves

are combined (center photo) by sewing, the trimmed to

final shape and the edges thoroughly sewn with a Zig-Zag

stitch. The end result (right photo above) is a nice belt

sheath for a spokeshave!

BELT SHEATH FOR A

LARGE PELLET PISTOL

A very inexpensive East German Day Pack gave its life to

make the holster shown above for a Daisy Avanti Powerline

747 pellet pistol. This material was too thick to

sew in multiple thicknesses, so I riveted on the belt loops

using common copper rivets. The clasp in front was

liberated from an East German grenade pouch. Because this

pistol is so long, I put a gromet at the bottom of the holster

so it could be tied to a pack or cart.

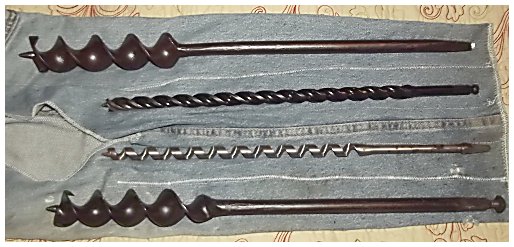

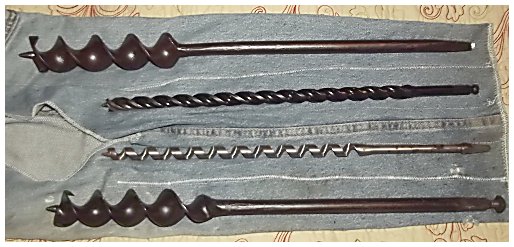

Wood Augers

|

|

|

|

Pant legs from

an old pair of Levi's sewn to make a sheath to keep the

auger bits secure in storage. When stored like this

the cutting edges don't get banged around and stay sharp

and clean. |

Part of a leg

from old Levi pants for storing the auger handles so they

are always clean, rust free and ready to use. |

DRAW KNIVES

|

|

|

| Draw knives

are used to remove bark and to shape logs, make flats on

logs, etc. The 6" draw knife is very handy to carry

and use when needed, but the handles are too close

together for working large logs and thus can cause real

knuckle bruising. There IS a use for large

fixed-handle draw knives, but for little jobs like tool

handles and small logs, these work fine. |

This shows why

I like folding handle draw knives - a sheath can hold one

right on a tool belt. |

KNIVES

|

|

|

| Three knives

hand forged from old files. The handles were made

from dry hardwood found in the forest, shaped and riveted

in place using nails for rivets and copper pennies as

washers. |

The leather

for the sheath was from an old tractor implement power

belt found in an abandoned barn, hand riveted so the

knives all nest as shown above. The cost? Some

nails, rivets, and pennies. |

Custom knife hand forged

from an old file

|

|

|

|

The knife and

sheath above illustrate that an outstanding and very

useful knife can be made with materials at hand.

A large file was annealed twice, hand forged to shape,

ground, sharpened, then hardened in a two-step

process, the back of the blade being spring temper and

the edge only being knife hard. The knife can

thus be used as a machete, clearing brush and chopping

down small trees, or be a fine combat knife if called

upon to do so. The sheath was made from plastic

cut from a thick blue 50 gallon barrel, glued and

riveted together. If the blade is kept clean and

oiled so that it does not rust, the knife and sheath

should last for the remainder of my lifetime and

another as well. This knife and sheath was made

for me by Chip Delyria. |

SHOVELS

|

The photo

at right shows a sheath I made for a medium sized camp

shovel using rubber from a truck inner tube. The

sheath was simply cut to fit using surgical shears,

then the sides pop riveted with washer backing to hold

the rubber securely. "Logger buttons" (suspender

buttons) were used to hold the cover flap closed. |

|

RELATED PAGES >

SHELTER

Cabin Building

Without Nails

CARPENTRY TOOLS FOR REPAIR AND CONSTRUCTION

Tools - Restoration

and Rebuilding

|

|

|